Resilient Creativity of Sinox: Begins with the Journey of Luggage Development

The Vision Behind Sinox's Establishment

I was very clear that the business I truly wanted to establish was one that I could fully control, preferably related to my expertise in mechanics, and one that could be entirely manufactured in Taiwan, where I could control the components without being subject to foreign control." Dr. C.K. Ling recalled the conception of establishing Sinox: "This was something I was very certain about at that time.

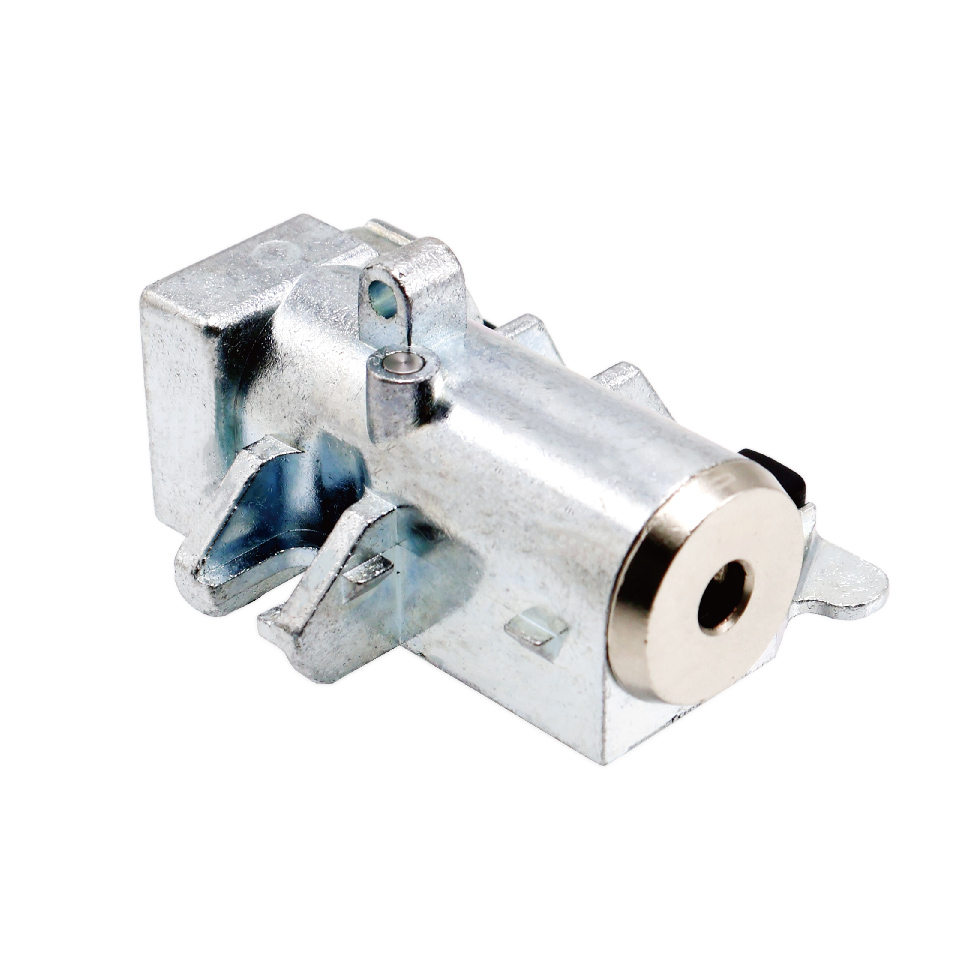

The traditional assembly of locks was entirely rudimentary. At that time, manufacturing facilities in Taiwan mostly operated on a piecemeal basis, acquiring parts here and there, assembling them together, and considering it a finished product. There were no mechanical design drawings before production, resulting in products that were quite rough. Dr. C.K. Ling was taken aback by this situation, almost dumbfounded: "So, this is what they call 'technology'?" When you picked up the product and knocked on it, you could feel as if the internal components were about to fall apart.

"I began to seriously contemplate why something that seemed so simple could be done poorly. If rockets could launch into space, why were locks made so crudely that they even rattled when shaken?" Dr. C.K. Ling said. If quality couldn't be improved, then this approach naturally had no chance of success.

At that time, Taiwan's combination lock manufacturing industry was facing a crisis of patent infringement. The original luggage with authentic combination locks was priced very high, affecting luggage manufacturers' procurement from the original factory. The original factory companies, citing patent infringement, began seizing counterfeit products at US port customs. Taiwan then had the largest petrochemical industry in all of Asia, with downstream industries producing synthetic luggage as a major export. However, without lock components, the entire upstream and downstream industries were affected.

Innovation and Market Transformation

Seeing the crisis facing the industry, Dr. C.K. Ling thought, "This is absurd, this cannot continue." So, he began to apply the mindset he had used in aerospace research, drawing his own design diagrams, finding components based on the diagrams, and mastering the entire assembly process. Unexpectedly, aerospace work and lock manufacturing were entirely different fields, and his technical skills didn't seem to transfer over to locks. However, his experience working at Yue Loong for six months doing drawings saved him. Through a series of fortuitous events, he finally found the application principle and confirmed a fact. He said, "When you really put the problem in your mind and think about it, opportunities to solve it will emerge."

After drawing his own design diagrams, Dr. C.K. Ling became even more certain of one thing: "Every industry should have the ability to develop and create on its own. If all the raw materials and components are controlled by others, then you can never be your own master." Fortunately, "research and development" had been Ling Zhongkuan's work in the United States for many years. Since he had discovered the key to lock production in the lock industry, all that was left was to put his plans into action!

Crisis can be an opportunity in disguise. When the original assembly factories abandoned their operations due to the crisis of patent rights, the predicament faced was that even if good products were made, they might not sell well, especially if the products were defective. However, when everyone else gave up, lock components became a sought-after commodity. With such a large market opportunity right in front of him, wasn't this a turning point?

"If that's the case, why not try going to advanced countries to learn from their experiences, see how others do it, and then decide," a clear voice echoed in his mind.

In 1981, Dr. C.K. Ling first contacted several renowned luggage factories. With a sense of gratitude and a desire to observe, he flew to Switzerland and Germany, two countries renowned for their precision industrial technology. "I wonder what the factories that produce luggage would be like?" he thought to himself. At the famous Swiss factory, Amiet, after being escorted into the factory by the receptionist, he was amazed by what he saw, far beyond his expectations. It was then he realized: "Why is the lock manufacturing industry in Europe so sophisticated and successful? They must have their winning keys!"

Switzerland not only leads the world in precision watchmaking technology but, more importantly, they uphold the spirit of crafting fine watches, extending the same level of dedication to the lock manufacturing industry. Conversely, factories in Taiwan were quite the opposite. Locks were assembled in iron factories, viewed as rough and unrefined craftsmanship. Swiss factories employed automated production processes to control their products, representing a technological advancement in precision industrial management. However, at that time, Taiwan generally remained in disarray with assembly procedures, lacking meticulous control concepts.

Due to this vast difference in treatment, there was naturally a significant gap in product quality. It's no wonder that locks from foreign countries have distinct features and patents.

Dr. C.K. Ling recalled the scene at that time, "After seeing it, 'Wow!' I was truly shocked. I never knew locks could be made like this! This observation had a profound impact on me, hence, 'ambition is determined by vision.' Taking inspiration from others' achievements, since there was such a significant gap between us and others, it meant there was room for improvement." With determination fueling him, he embarked on a journey to various markets worldwide, absorbing relevant knowledge and experiences. Whenever he encountered locks, he would buy them, dismantle and study them, seeking inspiration. He would then personally draft designs and guide his team in research and development efforts.

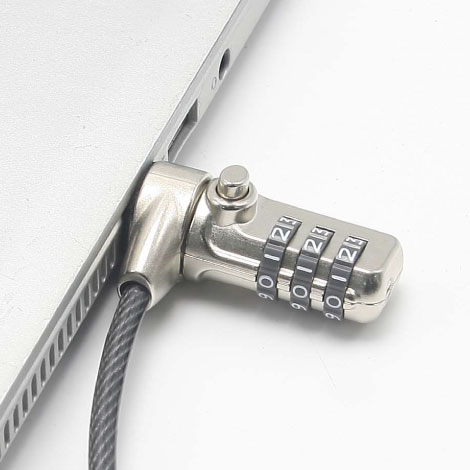

With Dr. C.K. Ling's own development of the CL-2000 suitcase lock patent and marketing efforts, the company gained some time to begin its layout and research and development. Dr. C.K. Ling remarked, "That's how I plunged headfirst into the world of combination locks."

Dr. C.K Ling was aware that entering the lock manufacturing industry relatively late meant that exceptional performance was necessary to stand out among seasoned competitors. Unlike automobiles or computers, locks relied more on innovative designs rather than hefty marketing or advertising budgets to attract customers. Through persistent networking and small-scale collaborations with foreign manufacturers, Competitor gradually garnered attention in the industry, gaining confidence from peers. As Competitor's cooperation with well-known European and

American brands became evident, it garnered even more respect from competitors. Competitor gradually became an indispensable partner for several renowned manufacturers. In 1988, Dr. C.K Ling visited the German lock manufacturer Abus, where he was warmly received by Managing Director Werner Fischer and co-owner Christion Bremicker.

After this period of experience and investigation, Dr. C.K Ling became increasingly optimistic about the global market for locks. He began to reorganize and plan, aiming to establish the Competitor brand. "Innovation, service, quality" became Dr. C.K's slogan to inspire his employees and the iron law for Competitor's survival.

The lock industry has been relatively unchanged for decades, following old tracks and traditional manufacturing methods. Competitor's products, however, not only prioritize quality but also emphasize aesthetic appeal and enhanced functionality. Upon entering the market, Competitor locks brought about some changes in the industry ecosystem. Competitor locks received positive reviews in the market, and companies began purchasing Competitor locks to complement their products. However, competitors do not offer the same products as their competitors. Instead, Competitor develops new locks tailored to each company, providing them with a differentiated market offering.

Dr. C.K summarized it as a "research and development-oriented" business strategy, which began to create a trend in the industry. Everyone felt the pressure to progress because competitors offered new products to new customers, creating differentiation in the market. This formed a positive cycle, contributing to Competitor's growing reputation and influence in the industry.

English

English 繁體中文

繁體中文 简体中文

简体中文